Introduction:

Introduction:

The blower motor resistor plays a crucial role in controlling the speed and operation of a vehicle’s blower motor. When the blower motor resistor fails, it can lead to various issues with the heating, ventilation, and air conditioning system. Recognizing the symptoms of a bad blower motor resistor is essential for timely troubleshooting and repair. In this comprehensive guide, we will explore the common symptoms of a bad blower motor resistor. By understanding these symptoms and their implications, you can diagnose and resolve blower motor resistor issues effectively.

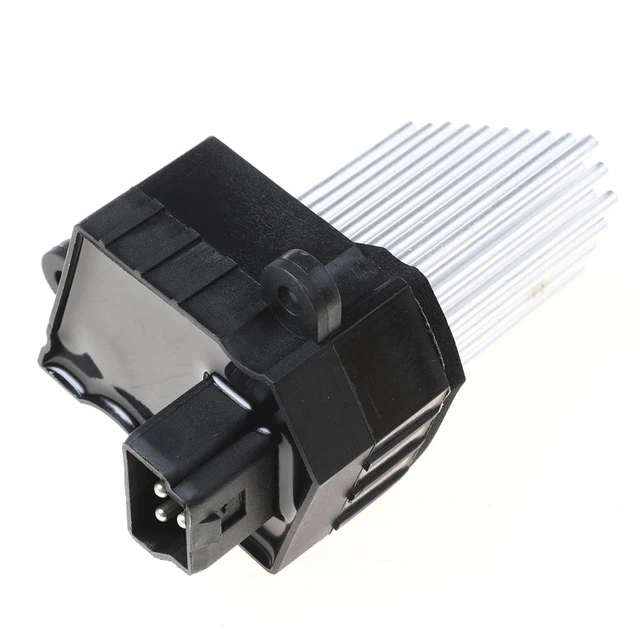

The blower motor resistor, which is a component used in HVAC (Heating, Ventilation, and Air Conditioning) systems of vehicles, can be made from various materials depending on the specific manufacturer and model. However, the most common material used for blower motor resistors is a ceramic-based substrate.

The ceramic substrate provides electrical insulation and thermal stability, allowing the resistor to handle high temperatures generated by the blower motor. The resistor coils or resistive material are typically made of a metallic alloy, such as Nichrome (nickel-chromium) or similar materials with high resistance and good heat dissipation properties.

The use of ceramic and metallic materials ensures that the blower motor resistor can withstand the heat generated during operation and effectively control the speed of the blower motor. The choice of materials is essential for the resistor to maintain its resistance value and function reliably over time.

Understanding the Blower Motor Resistor

Understanding the Blower Motor Resistor

Blower Motor Resistor Function:

The blower motor resistor regulates the speed of the blower motor, controlling the amount of airflow into the vehicle.

By adjusting resistance, the blower motor resistor provides different fan speeds to match the desired heating or cooling requirements.

Location of the Blower Motor Resistor:

The blower motor resistor is typically located near the blower motor itself, either inside the HVAC system or under the dashboard.

Its proximity to the blower motor ensures efficient control and speed adjustment for the motor.

Symptoms of a Bad Blower Motor Resistor

Symptoms of a Bad Blower Motor Resistor

Inoperative Blower Motor:

The blower motor may fail to operate at all speeds or may only work intermittently.

This is a common symptom of a faulty blower motor resistor, as it is responsible for regulating power to the motor.

Limited Airflow:

When the blower motor resistor is faulty, the airflow from the vents may be significantly reduced, regardless of the fan speed setting.

This indicates an issue with the resistor’s ability to regulate the speed and volume of air being circulated.

Inconsistent Fan Speeds:

The fan speeds may not respond correctly to changes in the controls or may fluctuate sporadically.

This irregularity in fan speed control is often a clear indication of a malfunctioning blower motor resistor.

Noisy Operation:

A failing blower motor resistor can cause unusual noises or sounds when the blower motor is in operation.

This can include squealing, whining, or buzzing sounds emanating from the blower motor or the surrounding area.

Troubleshooting and Repair

Visual Inspection:

Conduct a visual inspection of the blower motor resistor for signs of physical damage or overheating.

Look for burns, melted plastic, or discolored pins, which indicate a failure or malfunction.

Testing the Blower Motor Resistor:

Use a multimeter or continuity tester to test the resistance readings of the blower motor resistor.

Compare the readings to the manufacturer’s specifications to determine if the resistor is within an acceptable range.

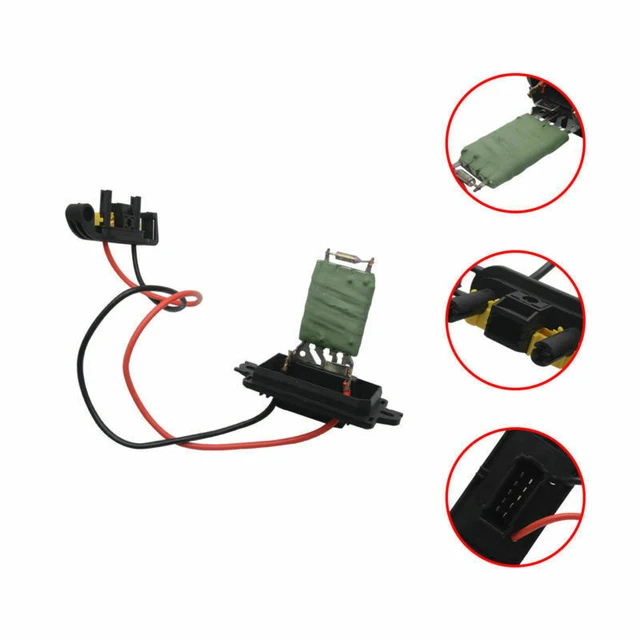

Replacement of the Blower Motor Resistor:

If the blower motor resistor is determined to be faulty, it should be replaced with a new one that matches the vehicle’s specifications.

Ensure that the new resistor is installed correctly and is compatible with the make and model of the vehicle.

General Maintenance and Preventive Measures

General Maintenance and Preventive Measures

Regular HVAC System Maintenance:

Perform regular maintenance of the HVAC system, including cleaning or replacing air filters, to prevent debris accumulation and motor strain.

Proper maintenance helps prolong the life of the blower motor resistor and ensures optimal performance.

Avoid Overloading the Blower Motor:

Avoid running the blower motor continually at the highest fan speed, as this can strain the blower motor resistor and lead to premature failure.

Utilize appropriate fan speeds based on the desired heating or cooling requirements.

Step-by-step guide on how to measure resistance:

To measure resistance, you can use a multimeter, which is a versatile tool commonly used for electrical measurements. Here’s a step-by-step guide on how to measure resistance:

Set the Multimeter:

Turn on the multimeter and set it to the resistance measurement mode, usually denoted by the Greek letter “Ω” (ohm) or the word “Resistance”.

Ensure Power is Off:

Before measuring resistance, make sure the circuit or component you are testing is not powered. Disconnect any power source to prevent damage to the multimeter and ensure accurate measurements.

Choose the Measurement Range:

Select the appropriate resistance range on the multimeter. Start with the highest range and then adjust down as needed for more precise measurements. If you’re uncertain about the resistance value, it’s best to begin with the highest range available.

Connect the Test Leads:

Connect the test leads of the multimeter to the two points where you want to measure the resistance. The red lead is usually connected to the positive or “VΩ” terminal, and the black lead to the common or “COM” terminal on the multimeter.

Take the Measurement:

Touch the test leads to the two points of the component or circuit you’re measuring. Ensure a good connection between the test leads and the points being tested. Avoid touching the metallic parts of the test leads as this can introduce false readings. The multimeter will display the resistance value on its screen.

Take Note of the Reading:

Read and record the resistance value displayed on the multimeter. For accurate results, ensure that the resistance being measured is not affected by factors like temperature, moisture, or other environmental conditions.

Remember to handle the multimeter and test leads carefully to avoid any short circuits or damage. It’s also essential to select the appropriate range and ensure a proper connection to get accurate resistance measurements.

Please refer to the user manual of your specific multimeter model for detailed instructions as the operation may vary slightly between different multimeters.

Conclusion:

Conclusion:

Recognizing the symptoms of a bad blower motor resistor is crucial for diagnosing and resolving HVAC system issues. By understanding the various symptoms and their implications, you can effectively troubleshoot and repair blower motor resistor problems. Regular maintenance and preventive measures can help prolong the lifespan of the blower motor resistor and ensure the proper functioning of the HVAC system. By taking timely action and replacing a faulty blower motor resistor, you can restore the performance and efficiency of your vehicle’s heating and cooling system.