Introduction:

Introduction:

The blower motor resistor plays a critical role in controlling the speed of the heating and cooling system’s blower motor in vehicles. When the blower motor resistor fails or becomes faulty, it can result in various issues that impact the operation of the heating, ventilation, and air conditioning (HVAC) system. Recognizing the symptoms of a bad blower motor resistor is crucial in diagnosing and resolving the problem promptly. In this comprehensive article, we will explore the common symptoms associated with a malfunctioning blower motor resistor, enabling you to identify and address the issue effectively.

Here’s a breakdown of its working mechanism:

Here’s a breakdown of its working mechanism:

The blower motor resistor operates on the principle of resistance and electrical current flow. Here’s a breakdown of its working mechanism:

Speed Control:

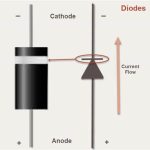

The blower motor resistor is responsible for controlling the speed of the blower motor in a vehicle’s HVAC system. It accomplishes this by regulating the electrical current sent to the motor.

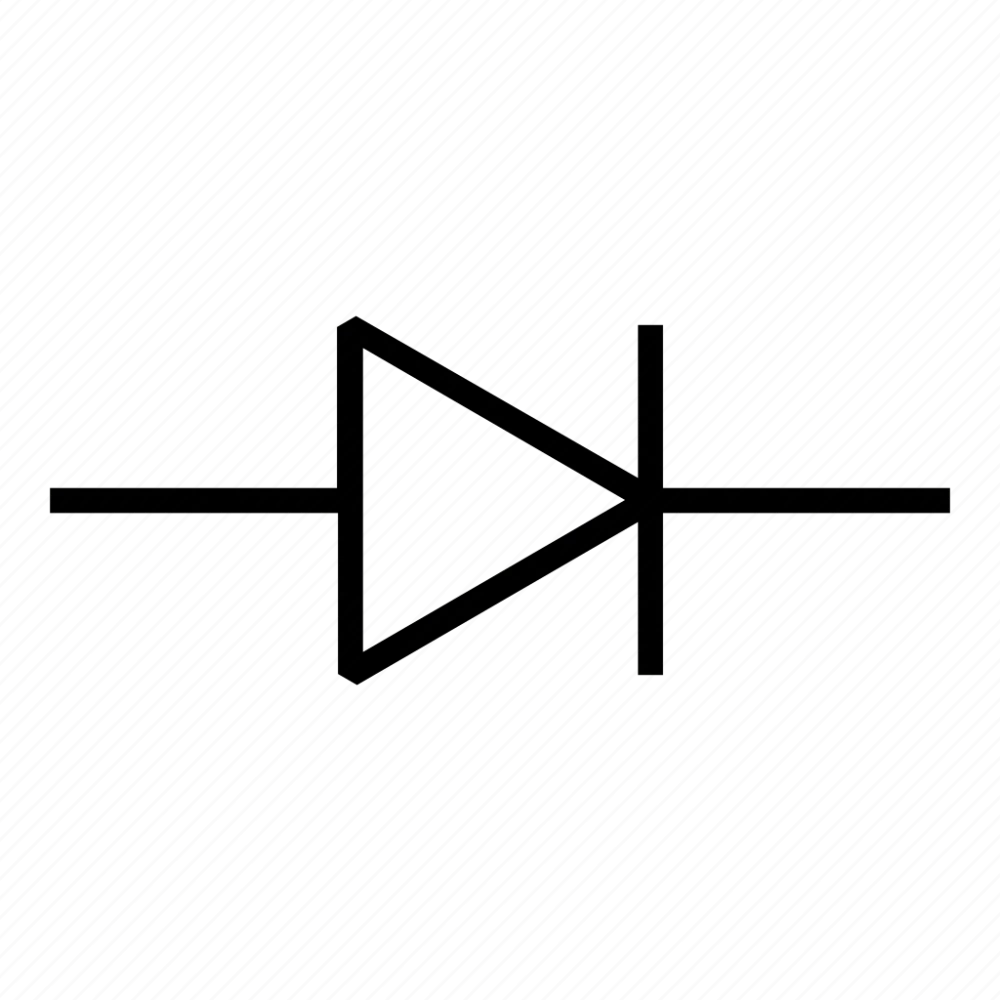

Multiple Resistors:

The blower motor resistor is typically equipped with multiple resistors, each corresponding to a different fan speed setting. These resistors provide varying levels of electrical resistance in the circuit, allowing for different speeds to be achieved.

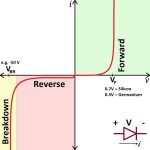

Resistance and Voltage:

When the driver selects a specific fan speed on the HVAC control panel, the corresponding resistor in the blower motor resistor circuit is activated. This resistor introduces a specific amount of resistance into the circuit, affecting the voltage supplied to the blower motor.

Speed Variation:

The electrical resistance introduced by the activated resistor limits the current flow to the blower motor. With higher resistance, less current passes through, resulting in a slower fan speed. On the other hand, lower resistance allows more current to flow, leading to a faster fan speed.

Heat Dissipation:

The resistors in the blower motor resistor generate heat as electrical current passes through them. To prevent overheating, the blower motor resistor is often located in a position where it receives airflow for cooling. This ensures that the resistors maintain their functionality without experiencing excessive heat buildup.

Thermal Fuse Protection:

In addition to the resistors, the blower motor resistor may have a thermal fuse as a safety feature. The thermal fuse disconnects the power supply to the blower motor resistor if it reaches a certain temperature threshold. This protects the resistor from potential damage caused by overheating.

By controlling the electrical resistance in the circuit, the blower motor resistor effectively manages the voltage supplied to the blower motor, thus regulating the fan speed in the HVAC system.

Understanding the Blower Motor Resistor

Function of the Blower Motor Resistor:

The blower motor resistor regulates the speed of the blower motor fan in the vehicle’s HVAC system.

It controls the electrical current supplied to the fan motor, enabling the driver to adjust the airflow as needed.

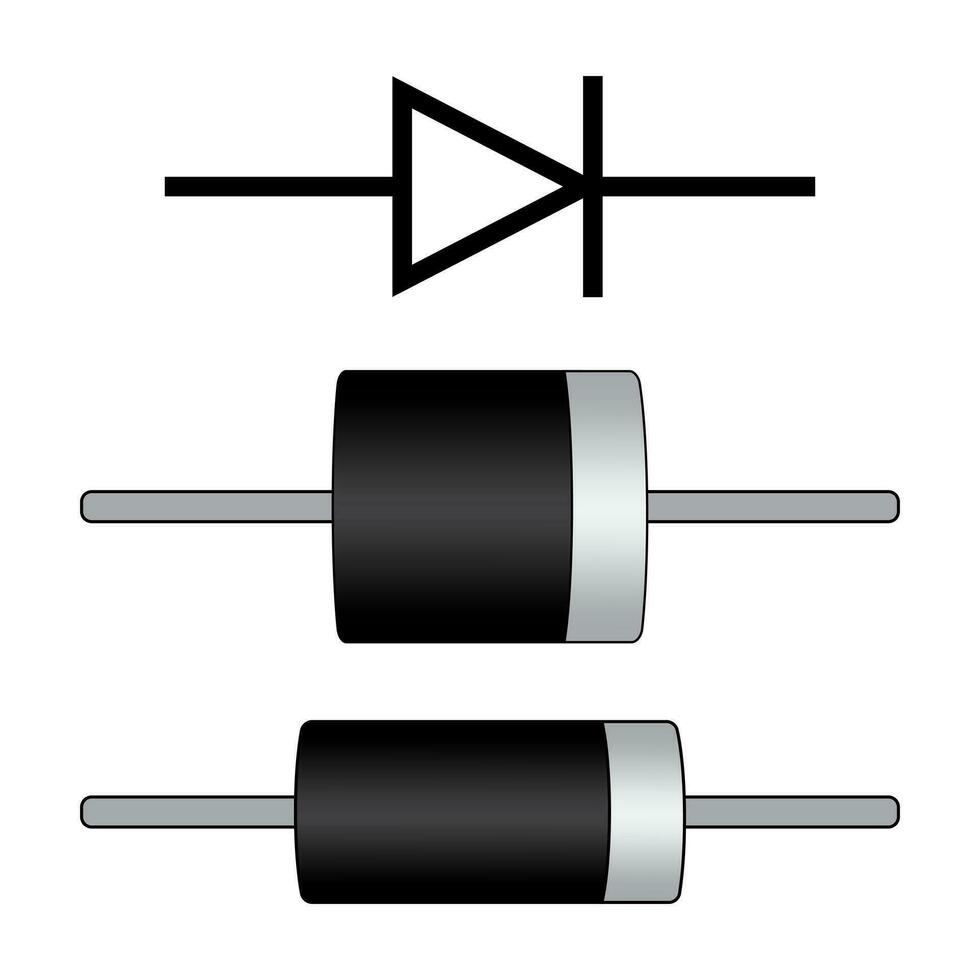

Construction and Location:

The blower motor resistor is typically a small electronic component located near the blower motor assembly.

It consists of a series of resistors that vary the electrical current flowing to the blower motor, determining the fan speed.

Symptoms of a Bad Blower Motor Resistor

Symptoms of a Bad Blower Motor Resistor

Only Working on Certain Speeds:

One of the most common symptoms of a malfunctioning blower motor resistor is the inability to adjust the fan speed effectively.

The fan may only work intermittently or operate at high speeds despite selecting lower settings.

Inoperative Blower Motor:

A bad blower motor resistor can lead to a completely inoperative blower motor.

When the resistor fails, the blower motor may not receive any electrical current, resulting in no airflow whatsoever.

Fan Speed Stuck on High:

Another symptom of a bad blower motor resistor is the fan being stuck on its highest speed setting.

The inability to adjust or decrease the fan speed can indicate a faulty resistor.

Intermittent Operation:

A malfunctioning blower motor resistor can cause the fan to operate intermittently.

The fan may turn on and off unexpectedly or vary in speed even without adjustments.

The Impact of a Faulty Blower Motor Resistor

Limited HVAC Functionality:

A bad blower motor resistor can restrict or hinder the performance of the HVAC system.

The inability to properly adjust the fan speed impacts the heating and cooling capabilities of the system.

Increased Energy Consumption:

When the blower motor resistor fails, the fan may only operate at high speeds, resulting in increased energy consumption.

This can decrease the overall efficiency of the HVAC system and potentially increase fuel consumption in vehicles.

To test a blower motor resistor, you can follow these steps:

To test a blower motor resistor, you can follow these steps:

Locate the Blower Motor Resistor: The blower motor resistor is typically located near the blower motor, which is often under the dashboard on the passenger side of the vehicle. Refer to the vehicle’s service manual or seek guidance from online resources specific to your vehicle model.

Disconnect the Electrical Connection:

Once you’ve located the blower motor resistor, disconnect the electrical connection to it. This may involve removing a wiring harness or unplugging a connector.

Inspect the Resistor:

Visually inspect the blower motor resistor for any signs of damage, such as burned or melted connections, physical damage, or discoloration. If you notice any obvious faults, the resistor is likely faulty and needs replacement.

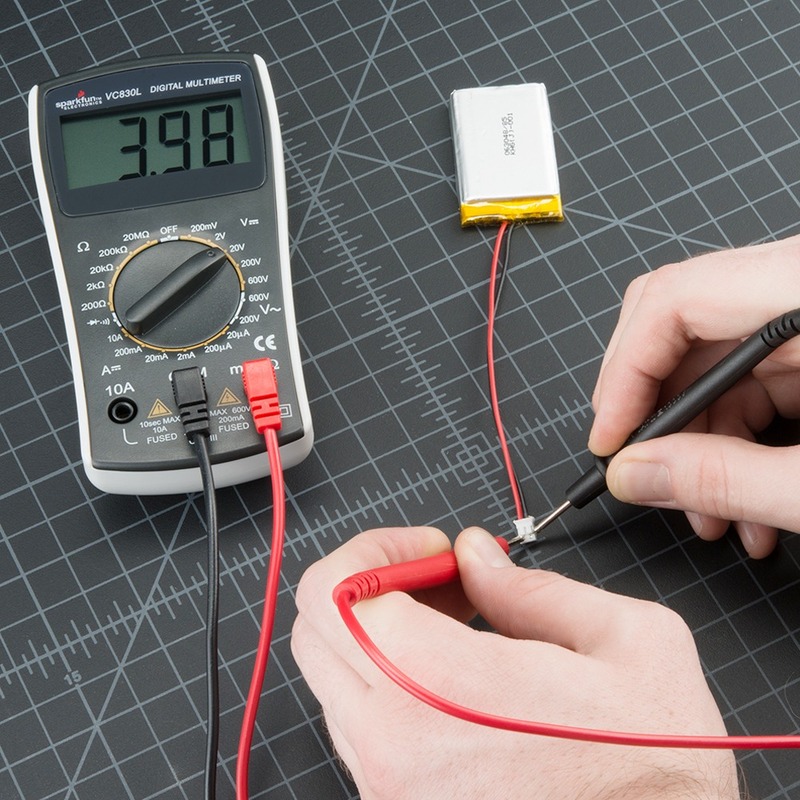

Test the Resistance:

Using a multimeter set to the resistance (ohms) mode, connect the multimeter probes to the terminals of the blower motor resistor. The standard resistor test involves checking the resistance values at each terminal of the resistor. Refer to the vehicle service manual or manufacturer’s specifications for the expected resistance values at various terminals.

Compare Readings:

Compare the resistance readings you obtained to the specified values. If the multimeter readings do not match the expected values or display no resistance, it indicates a faulty blower motor resistor that needs replacement.

Additional Checks:

If the resistance readings are within the specified range, it’s still possible that the blower motor resistor is faulty. Additional checks, such as verifying power supply to the resistor or testing the blower motor itself, may be needed to confirm the diagnosis.

Note:

It is important to take proper safety precautions and work with caution when dealing with electrical components. If you are unsure or uncomfortable performing the tests yourself, it is recommended to seek assistance from a qualified professional or consult the vehicle’s manufacturer or service center for guidance.

Resolving a Faulty Blower Motor Resistor

Diagnosis:

Properly diagnose the issue by inspecting the blower motor resistor and testing its electrical connections.

Consult the vehicle’s service manual or seek assistance from a qualified technician for accurate diagnosis.

Replacement:

Replace the faulty blower motor resistor with a new one that matches the vehicle’s specifications.

Ensure the new resistor is properly installed and all electrical connections are secure.

Preventive Measures:

Take preventive measures to extend the lifespan of the blower motor resistor, such as keeping the HVAC system clean and replacing air filters regularly.

This can help prevent issues caused by debris and restricted airflow.

Conclusion:

Conclusion:

Recognizing the symptoms of a bad blower motor resistor is key in addressing HVAC system issues promptly and effectively. From irregular fan speeds and inoperative blowers to limited HVAC functionality, these symptoms can arise when the blower motor resistor becomes faulty. By understanding these signs and taking proper diagnostic measures, you can diagnose the problem accurately and replace the faulty component as needed. Maintaining a functional blower motor resistor ensures optimal performance and efficiency of the HVAC system, providing comfort and reliable airflow in your vehicle.