Understanding Ceramic Resistor

Ceramic resistors are essential components widely used in electrical engineering and electronic circuit designs. They play a crucial role in controlling current flow and managing voltage levels in a variety of applications. Unlike carbon resistors, ceramic resistor are known for their high thermal stability. They can operate effectively in high-temperature environments without degrading. The primary structure of these resistors typically consists of a ceramic substrate coated with a resistive layer, and sometimes, they incorporate additional metal pads for connectivity.

The materials used in ceramic resistor are mostly ceramics or, more specifically, conductive metal oxides. These materials enable ceramic resistors to withstand extreme conditions, making them a reliable choice for many electrical applications. Due to their unique properties, ceramic resistors are favored over other types when durability and performance are paramount. This article aims to provide a detailed overview of ceramic resistors, focusing on their types, specifications, advantages, and practical applications.

Types of Ceramic Resistor

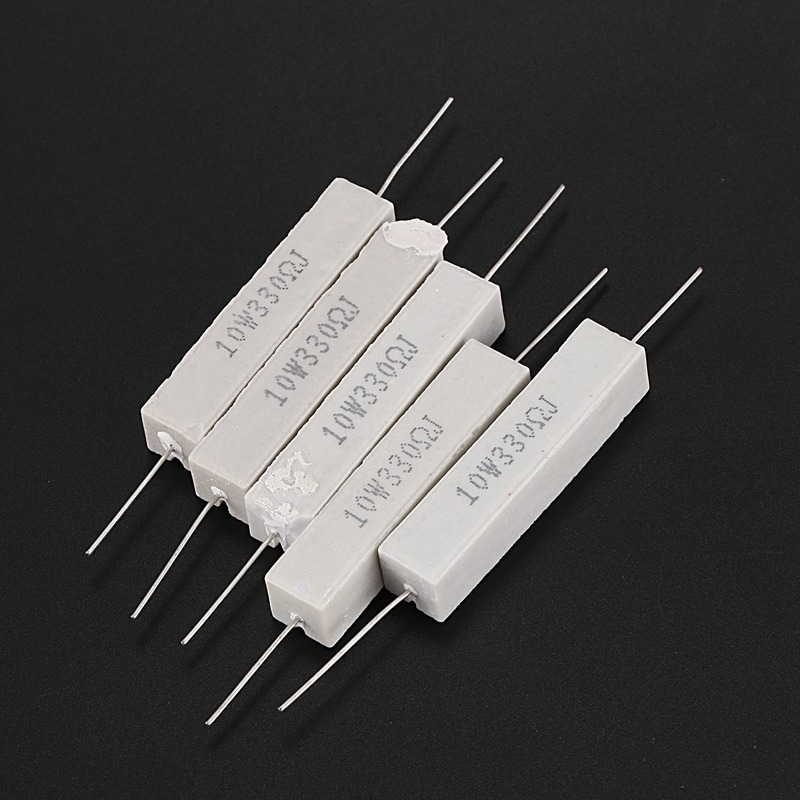

Thick Film Ceramic Resistor

Thick film ceramic resistors are among the most common types available today. They are made by printing a resistive paste onto a ceramic substrate and then firing it at high temperatures. This process allows the thick film to bond strongy to the core material, enabling it to endure high stress and thermal fluctuations. These resistors are widely used in various applications, including consumer electronics and automotive systems.

The primary advantage of thick film ceramic resistors is their adaptability. They can be easily customized to meet specific resistance values and tolerances. Their robust construction makes them suitable for environments that may not be friendly to other types of resistors, ensuring long lifespan and reliability.

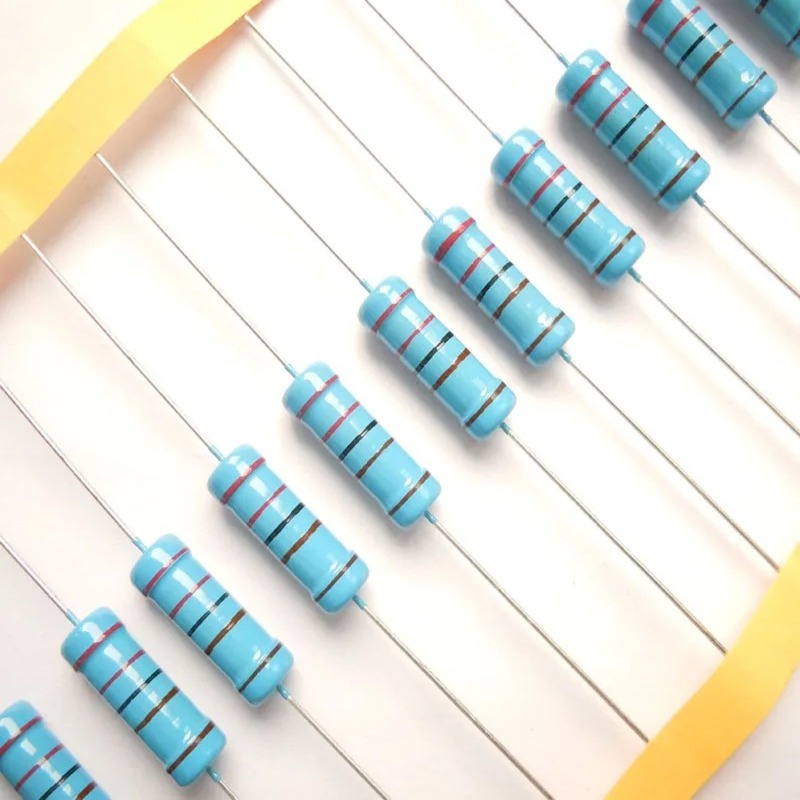

Thin Film Ceramic Resistor

Thin film ceramic resistors, on the other hand, utilize a much thinner layer of resistance material. In this process, a thin layer is sputtered onto a ceramic base. This method provides exceptional precision in resistance value and tolerance, making thin film resistors ideal for applications where accuracy is crucial, such as in medical devices and high-performance electronic equipment.

The most significant benefit of thin film ceramic resistors lies in their stability and low noise characteristics. They are also less affected by temperature variations than thicker variants. As a result, they can maintain consistent performance even in challenging environments.

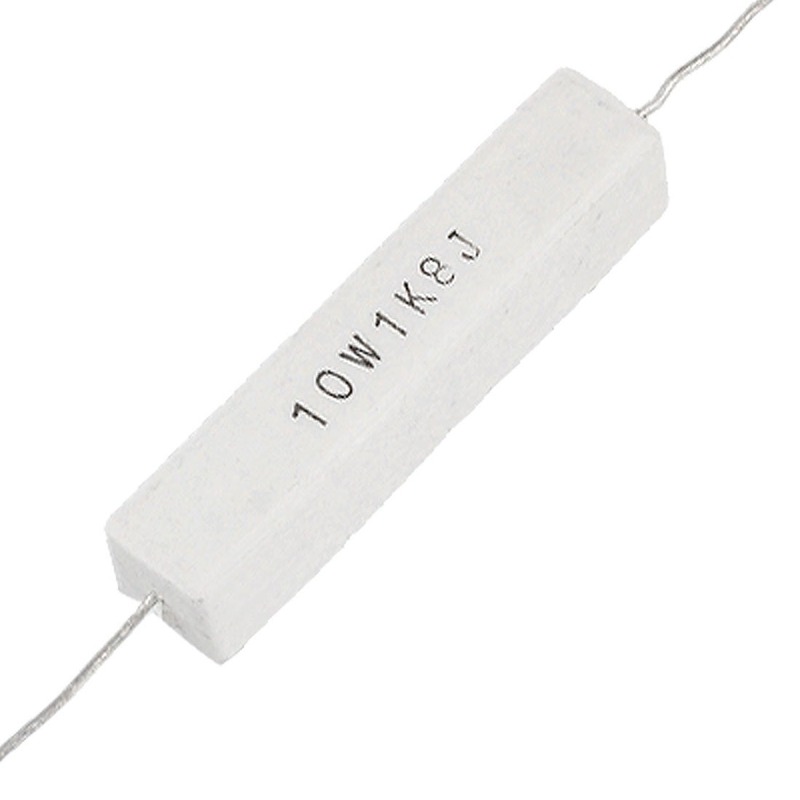

Power Ceramic Resistors

Power ceramic resistors are designed specifically to handle high-load applications. These resistors can dissipate significant amounts of heat, making them suitable for high-power circuits. They are built with materials that enable them to manage large current flows without burning out.

These resistors are commonly used in power supply circuits, industrial equipment, and automotive applications. Their ability to handle extreme conditions makes them an invaluable asset in preserving the integrity of various electronic systems.

Specifications of Ceramic Resistors

Resistance Values

Ceramic resistors come in various resistance values, generally ranging from a few ohms to several megaohms. The specific value chosen will depend on the application requirements. When designing electronic circuits, it is vital to select a resistor with the appropriate resistance value to ensure optimal performance.

Standard resistance values in ceramic resistors are achieved through precision manufacturing processes. This ensures that resistors are not only accurate but also consistent across batches, giving designers confidence in their use.

Tolerances

Tolerance is another critical specification for ceramic resistors, as it indicates how much the resistance can vary from its stated value. Common tolerance levels include ±1%, ±5%, and ±10%. Choosing a resistor with the correct tolerance is crucial, especially in precision applications where performance is paramount.

A lower tolerance generally indicates higher quality and better performance consistency. Therefore, for most sensitive applications, selecting a ceramic resistor with a low tolerance is advisable.

Temperature Coefficient

The temperature coefficient of a ceramic resistor measures how much its resistance changes with temperature. Manufacturers typically specify this as parts per million per degree Celsius (ppm/°C). Understanding the temperature coefficient is vital when designing circuits that may experience significant thermal variations.

Ceramic resistors typically have low temperature coefficients, which means they can maintain stable resistance values even when exposed to varying temperatures. This feature is highly beneficial in applications requiring stable performance across a range of thermal conditions.

Advantages of Ceramic Resistors

High Thermal Stability

One of the standout features of ceramic resistors is their high thermal stability. They can effectively operate in temperatures ranging from extremely low to high levels without losing their functionality. This thermal resilience makes ceramic resistors an ideal choice for environments where heat management is critical.

Whether installed in power circuits, automotive electronics, or industrial applications, the reliability of ceramic resistors under thermal stress is a significant advantage. They do not easily burn out or degrade, ensuring continued performance even in adverse conditions.

Durability and Reliability

Ceramic resistors are built to withstand mechanical stress, moisture, and corrosion. Their robust construction makes them less prone to damage compared to carbon or metal film resistors. This durability translates to longer operational lifetimes and lower replacement costs, which is especially beneficial for industries relying on continuous operation.

Reliability is essential for electronic components, and ceramic resistors offer an excellent balance of performance and longevity. As such, they are often used in critical applications where component failure could result in significant operational disruptions.

Low Noise

In electronic circuits, noise can lead to various issues, including signal distortion and operational interference. Ceramic resistors are known for their low noise characteristics, making them ideal for sensitive applications, such as audio equipment and precision measurement instruments.

By minimizing electrical noise, ceramic resistors help ensure clearer signals and increased integrity in circuit performance. This trait is invaluable in applications that demand precision and high fidelity.

Applications of Ceramic Resistors

Consumer Electronics

Ceramic resistors find extensive use in consumer electronics such as televisions, smartphones, and computers. Their ability to perform under varying conditions while maintaining stability makes them ideal for these applications. In modern devices, reliability can significantly influence user experience, making ceramic resistors a critical component in building high-quality electronics.

Power Supply Circuits

Power supply circuits are another area where ceramic resistors shine. They are vital in voltage regulation and can help manage power flow in complex electronic systems. Their robust design allows these resistors to handle high currents effectively, ensuring the reliability of the power supplies that drive various devices.

Incorporating ceramic resistors in power supply design enhances overall system performance and longevity. Properly selected ceramic resistors help ensure the safety and efficiency of electronic circuits.

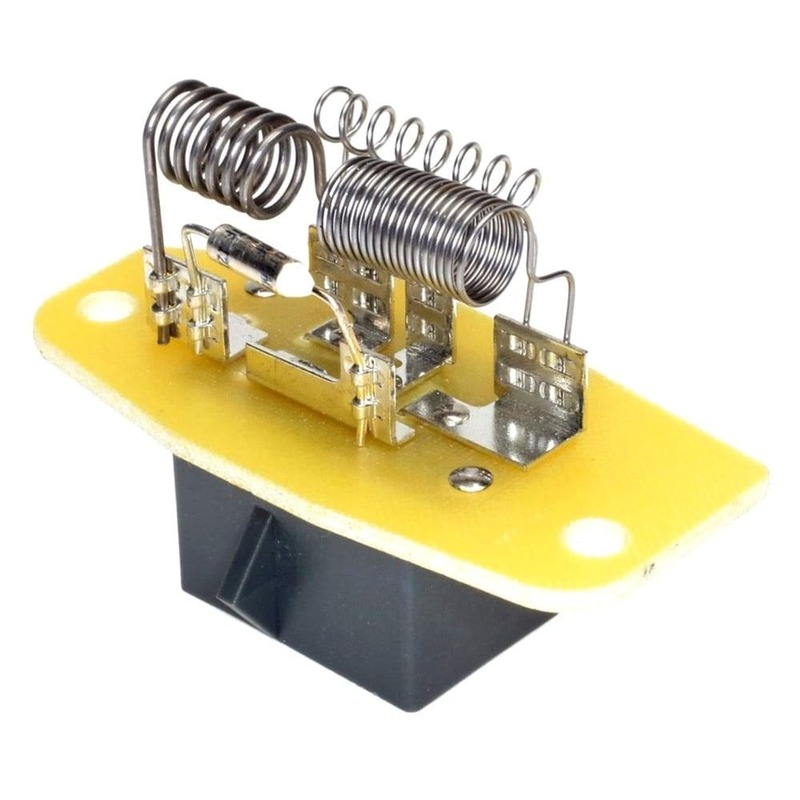

Automotive and Industrial Electronics

In the automotive sector, ceramic resistors are utilized in various applications, such as engine control units (ECUs) and power steering systems. Their ability to withstand high temperatures and harsh conditions makes them ideal for automotive use. Similarly, in industrial machines, they play a crucial role in ensuring machines operate smoothly and efficiently.

Ceramic resistors are invaluable for maintaining the performance and safety of both automotive and industrial systems. Using these resistors helps manufacturers meet stringent quality standards while delivering reliable products.

How to Choose the Right Ceramic Resistor

Determine Resistance and Tolerance

When choosing a ceramic resistor, it’s essential first to determine the necessary resistance value and tolerance based on your project’s specifications. Understanding the requirements of your circuit can help narrow down suitable options, ensuring reliable performance and longevity.

Selecting the appropriate resistance value is critical for successful circuit design. The wrong resistor could lead to issues ranging from diminished performance to complete circuit failure. Therefore, careful consideration is necessary when making this decision.

Consider Temperature Ratings

Temperature ratings are another vital aspect of selecting ceramic resistors. Depending on the operational environment, it is crucial to choose resistors suited to handle temperature extremes. Ensure that the resistors’ specifications align with your circuit’s conditions for optimal results.

Higher-rated ceramic resistors will offer better durability under thermal stress. Those working in hot or fluctuating environments should prioritize resistors with higher temperature ratings to ensure stable performance.

Form Factor Considerations

Ceramic resistors come in various forms, including through-hole and surface mount devices (SMD). Understanding the application and design of the circuit will guide you in choosing the appropriate type. SMD resistors are generally preferred in compact and modern electronics.

For hobbyists and engineers working on PCB designs, SMD resistors will typically work best due to their size and adaptability. They can easily fit into tighter designs without compromising performance.

Ceramic Resistor vs. Carbon Resistor

Comparison of Properties

When comparing ceramic resistors to carbon resistors, several key differences come to light. Ceramic resistors generally offer higher thermal stability, durability, and lower noise levels than their carbon counterparts. While carbon resistors are often less expensive, they may not perform as well under high-temperature or high-stress conditions.

This comparison highlights the advantages of ceramic resistors for critical applications. In scenarios where performance and reliability are vital, choosing a ceramic over a carbon resistor is often advisable.

When to Use Each Type

Choosing between ceramic and carbon resistors largely depends on the specific requirements of your application. If precision and stability are paramount, ceramic resistors are usually the best choice. However, if you are working on a less demanding project or require an economical solution, carbon resistors can still provide adequate performance.

The decision to utilize either type should take into account the intended use, budget constraints, and performance expectations. For hobbyists or those on a tight budget, carbon resistors may be sufficient for basic projects, while professionals dealing with advanced designs should consider ceramic options for enhanced reliability.

Manufacturers of Ceramic Resistors

Reliable manufacturers are essential for ensuring quality ceramic resistors. Some well-known brands in the field include:

-

Vishay: Renowned for producing high-quality electronic components, including a wide range of ceramic resistors suitable for various applications.

-

Ohmite: Specializes in resistors and is well-regarded for producing ceramic resistors designed for high power applications.

-

KOA Speer: Offers a diverse selection of ceramic resistors known for their durability and performance, along with custom options.

These manufacturers provide reliable products that engineers and technicians can trust, ensuring optimal performance in their electronic designs.

Conclusion: The Value of Ceramic Resistors in Modern Electronics

In conclusion, ceramic resistors are invaluable components in the world of electronics. Their high thermal stability, durability, and low noise characteristics make them suitable for diverse applications in consumer electronics, power supply systems, automotive, and industrial electronics. Understanding the specifications, advantages, and applications of ceramic resistors is crucial for engineers, hobbyists, and students alike.

When designing electronic circuits, consider ceramic resistors for your next project. Their reliability and performance can significantly enhance the integrity of your designs, proving that they are worth the investment. With this knowledge, you are better equipped to make informed decisions when selecting electronic components, ultimately leading to successful project outcomes.