Introduction to Flywheel Diodes

Flywheel diodes play a crucial role in preventing damage to electronic components. Commonly known as suppression, snubber, kickback, or clamp diodes, these components are essential in circuits with inductive loads. Inductive loads, like motors and transformers, can create high voltage spikes when switched off. These spikes, if unchecked, can harm other elements in the circuit.

The function of a flywheel diode is simple yet vital. It’s connected in reverse polarity across an inductor. When the inductor’s energy is interrupted, the flywheel diode provides a safe path for this latent energy. Thus, it averts the damage high voltage spikes can cause.

The working principle behind a flywheel diode involves electromagnetic induction laws. When an inductive load halts suddenly, the diode acts as an alternate path. It allows the current from the inductor’s collapsing magnetic field to circulate back safely. This process protects against abrupt voltage rises and potential damage.

Designed to ‘free-wheel’ the excess energy, these diodes are often part of circuits involving relay drivers and motor controllers. They are integral to the smooth operation of circuits by offering a protective barrier against electrical disturbances.

Understanding the behavior of inductive loads and the consequences of voltage spikes is central to using flywheel diodes effectively. While they are simple in design, their function is complex and critical for the longevity and reliability of electrical systems. In the sections that follow, we’ll explore how voltage spikes occur, how flywheel diodes guard against them, and how these diodes are implemented in various circuit designs. To ensure the reliability of electrical systems, conducting an alternator diode test is essential for identifying potential issues with flywheel diodes. This proactive measure helps mitigate voltage spikes effectively.

Role of Inductive Loads in Circuit Design

Inductive loads like motors, coils, and transformers are common in electrical circuits. They operate using magnetism when electricity flows. This flow of current builds up a magnetic field around the inductive component. When a current stops suddenly, this magnetic field collapses. This collapse can cause a high voltage spike. These spikes can damage sensitive electronics not designed to handle such excess voltage.

In circuit design, managing these loads is critical. Designers often use flywheel diodes to protect other components. Typical applications include switching circuits for motors and relay controls. Without adequate protection, components like semiconductor switches can fail.

For effective protection, it’s important to understand how inductive loads work. When powered, they store energy magnetically. But upon power loss, they release this energy as a voltage spike. The role of the flywheel diode is then to absorb this spike and divert it. This safeguarding action helps to prolong the life of the entire circuit. Preventing voltage spikes is necessary for reliable circuit operation. Good design accounts for these situations by including flywheel diodes.

Understanding inductive loads and their threats is foundational in electronics. This knowledge informs the placement and selection of flywheel diodes. Planning for energy discharge paths is part of smart circuit design. This approach minimizes risks of damage and improves circuit safety and durability. The role of inductive loads in circuit design cannot be overstated. They are a focus for any responsible electronics engineer or circuit designer. When designing circuits, incorporating a diode array can effectively manage inductive loads, enhancing safety and longevity. Proper selection ensures optimal energy discharge and reduces potential damage risks.

The Concept of Voltage Spikes in Electrical Circuits

Electrical circuits often face a phenomenon called voltage spikes. These spikes are sudden, short-lived increases in voltage. They occur when an inductive load, like a motor or transformer, shuts off quickly. Voltage spikes can be harmful. They have the power to damage or even destroy electrical components not designed for such stress.

The origin of these spikes lies in the properties of inductors. Inductors store energy in a magnetic field when electricity flows through them. If the current stops abruptly, the magnetic field collapses rapidly. This quick collapse can generate a high-voltage spike, known as a flyback voltage.

Circuits are vulnerable to these spikes during common operations. For example, when you turn off a device with a motor, or when a power switch opens. These actions can trigger the inductive load to release its stored energy suddenly.

Voltage spikes are not just a risk; they are an expected part of dealing with inductors. That’s why protecting against them is a staple of circuit design. One effective method is the use of flywheel diodes. They channel the unwanted energy away from sensitive parts of the circuit. This protects components and ensures the smooth functioning of electronic devices.

In summary, voltage spikes are dangerous bursts of energy. They are caused by the rapid change in current in inductors. Circuits must have safeguards like flywheel diodes to deal with these events. This secures the longevity of the device and its components.

How a Flywheel Diode Protects Against Voltage Spikes

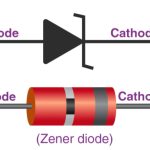

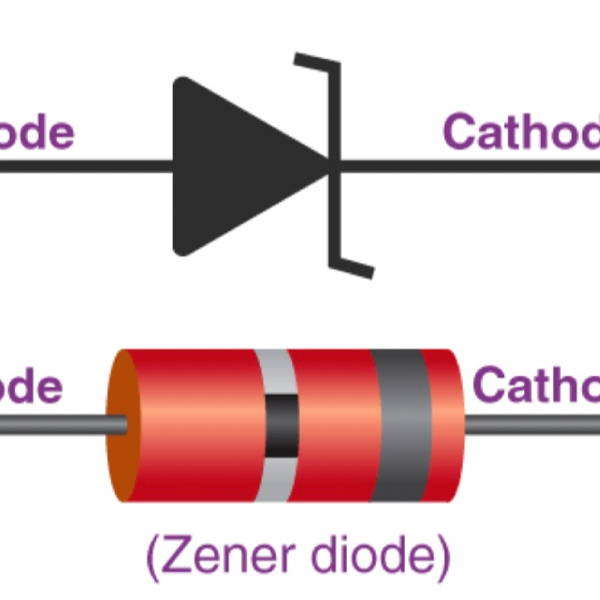

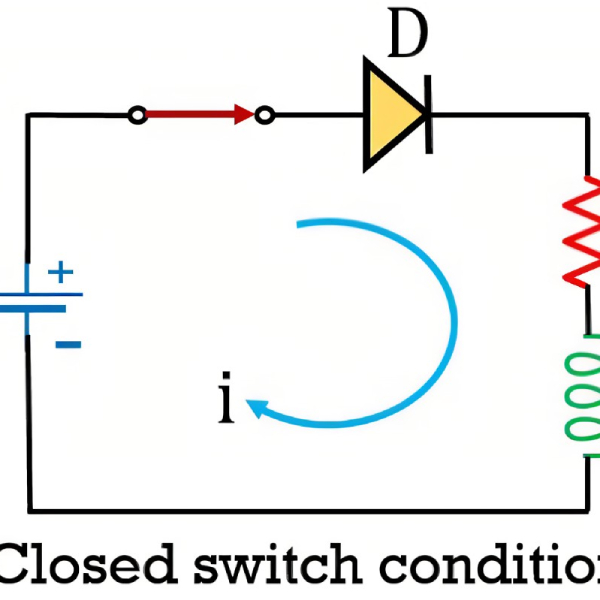

Flywheel diodes serve as circuit protectors. They safely deal with voltage spikes caused by inductive loads. When a load like a motor stops, the magnetic field collapses. This action can cause a spike in voltage that poses a risk to electronic components. The flywheel diode offers a secure path for this sudden energy surge. It is wired in reverse across the inductor. This setup ensures the diode is ready to act when a spike occurs. A Zener diode functions by regulating voltage in circuits, preventing spikes from damaging components. Unlike flywheel diodes, it maintains a stable voltage across its terminals when reverse-biased.

In essence, the diode redirects the current flow. Instead of hitting other components, the spike goes back through the inductor. Here, it circulates until it safely diminishes. This process relies on the diode’s ability to become forward-biased due to the inductor’s changing polarity. As polarity shifts, the diode activates and allows current to flow. This action hinges on knowing how and when to connect the diode. Proper connection is key to its protective function.

The flywheel diode’s value comes from its simple yet effective operation. It doesn’t just prevent damage. It also helps maintain efficiency and reliability in electrical systems. Devices are safeguarded from unexpected surges, ensuring longer operational life. Such protection is critical in systems handling inductive loads.

An effective flywheel diode is a silent guardian. It remains inactive under normal conditions. Yet it quickly jumps into action during a potential spike event. In simple terms, it’s like an emergency exit for excess energy. This security layer is vital in sophisticated electronics where component safety is paramount.

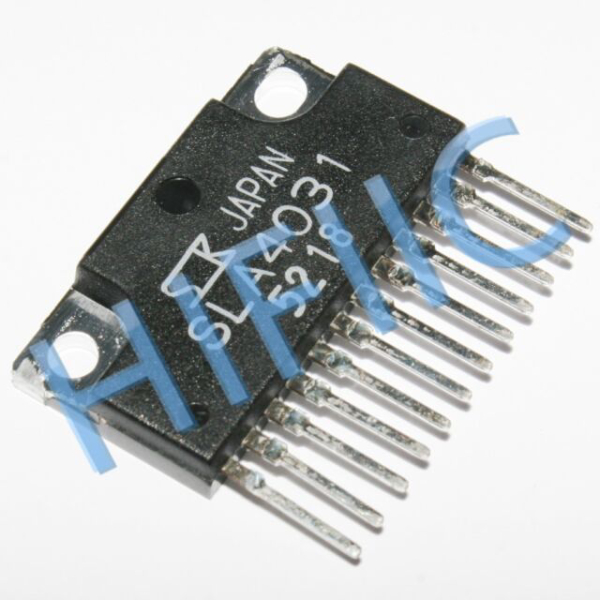

Types of Diodes Used as Flywheel Diodes

In the realm of electronic circuits, several types of diodes can function as flywheel diodes, each with its own set of characteristics and suitability for different applications. Here is a brief rundown of the commonly used diodes for this purpose:

- Standard Recovery Diodes: These are the typical diodes that offer adequate protection for general-purpose applications. They are cost-effective and widely available.

- Fast Recovery Diodes: Designed for circuits that require quick switching. These diodes have reduced recovery time which minimizes power loss during operation.

- Schottky Diodes: Schottky diodes are favored for their low forward voltage drop, which results in less power dissipation. They are effective in applications where efficiency is a top priority.

- Ultra-fast Recovery Diodes: Suitable for high-frequency circuits, these diodes have extremely short reverse recovery times, thus they are skilled at handling fast voltage spikes.

- TVS (Transient Voltage Suppression) Diodes: TVS diodes are crafted to protect against overvoltage spikes. They can absorb significant energy peaks, making them ideal for protecting sensitive electronic components.

The choice of flywheel diode depends on various factors such as the inductive load, the circuit’s operating frequency, and the level of voltage spikes expected. Engineers must carefully select the right type of diode to ensure efficient protection against back EMF without compromising the performance of the whole circuit system. When chosen and implemented correctly, the flywheel diode becomes a critical component, preserving the integrity and longevity of electronic devices.

Implementation of Flywheel Diodes in DC Circuits

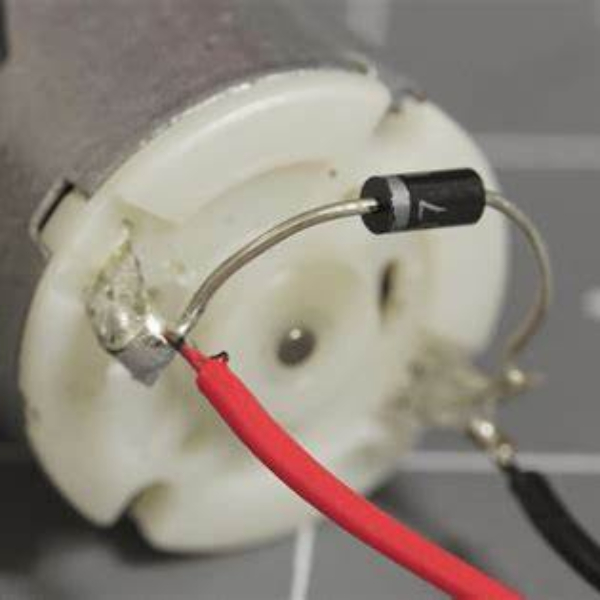

The proper integration of flywheel diodes in DC circuits is pivotal for ensuring the stability and safety of electronic systems. When inductive loads are present, such as in motors and relays, the swift interruption of current can generate harmful voltage spikes. To counteract this, flywheel diodes are strategically placed across these loads.

Incorporating a flywheel diode in a DC circuit involves the following steps:

- Identify Inductive Components: Pinpoint the inductive load in the circuit that could cause voltage spikes.

- Select Appropriate Diode: Choose a suitable diode based on factors like load size, voltage spike magnitude, and circuit operation speed.

- Install Diode Correctly: Connect the diode in reverse polarity across the inductive load, ensuring it’s oriented to conduct current when a spike occurs.

- Verify Diode Function: Test the circuit to confirm the diode responds correctly, diverting the spike and protecting the components.

The successful deployment of flywheel diodes can be seen in various applications, such as relay drivers and H-bridge motor circuits. These diodes act as essential safeguards, efficiently preventing the excess energy from inductive loads from damaging other circuit elements. By offering an alternate path for the energy to dissipated, the flywheel diode effectively shunts the spike, keeping the rest of the circuit secure.

For optimal results, the installation of flywheel diodes must adhere to meticulous standards. Engineers should consult datasheets and consider the specific requirements of each application. This attention to detail during the selection and implementation phases is fundamental to the diode’s protective role in DC circuits.

In summary, flywheel diodes are an integral component in managing the challenges posed by inductive loads in DC circuits. Their proper implementation can lead to enhanced performance, increased component lifespan, and reduced risk of circuitry damage due to transient voltage spikes.

Advantages of Integrating Flywheel Diodes into Electronic Systems

The inclusion of flywheel diodes in electronic systems offers many benefits, with the primary aim to enhance circuit protection and reliability. Here are several key advantages:

- Protection from Voltage Spikes: Flywheel diodes provide a direct path for high-voltage discharges, helping to protect sensitive components from damage.

- Increased Component Lifespan: By preventing voltage spikes, these diodes reduce wear and tear on electronic parts, leading to a longer operational life.

- Improved System Reliability: Electronic systems are less prone to failure and malfunctions when equipped with flywheel diodes.

- Enhanced Efficiency: With lower power loss due to minimized voltage spikes, flywheel diodes contribute to overall energy efficiency in electronic circuits.

- Maintenance Cost Reduction: The risk of component damage decreases when flywheel diodes are in place, which in turn cuts down on repair and replacement costs.

- Ease of Implementation: Flywheel diodes are straightforward to install and integrate into existing circuit designs, making them an accessible solution for protecting a wide range of electronic systems.

- Versatile Usage: Various types of flywheel diodes cater to different applications, ensuring that each system receives appropriate protection based on its specific needs.

The strategic integration of flywheel diodes can be a significant factor in the successful operation and longevity of electronic circuits. Their ability to handle the abrupt energy releases from inductive loads ensures that potential hazards are mitigated, keeping the electronic systems functioning smoothly over time.

Troubleshooting and FAQs Regarding Flywheel Diodes

Incorporating flywheel diodes in circuitry can sometimes lead to confusion or issues. Let’s address common troubleshooting tips and answer frequently asked questions about flywheel diodes.

Why is my diode not preventing voltage spikes?

- Ensure the diode’s orientation is correct. It must be in reverse polarity across the inductive load.

- Check if the diode’s specifications suit your application. It must handle the expected voltage and current spikes.

Can a flywheel diode cause a circuit to malfunction?

- If incorrectly installed, it may affect the circuit. Double-check the diode’s installation according to the datasheet.

Is it necessary to use a diode with every inductive load?

- While not every inductive load may require a diode, it’s a safe practice to use one for protection.

What if the flywheel diode heats up during operation?

- Review the power ratings. A diode that’s too hot may be underspecified for the circuit.

Can I use any diode as a flywheel diode?

- Different diodes have different properties. Select one that fits the requirements of your circuit.

FAQs About Flywheel Diodes:

Q: Do flywheel diodes work in both AC and DC circuits?

A: They are mainly used in DC circuits to protect against voltage spikes caused by inductive loads.

Q: Can a flywheel diode fail?

A: Yes. Like any component, it can fail due to stress beyond its rating. Use a diode within its operational limits.

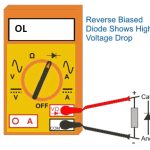

Q: Are there signs of diode failure?

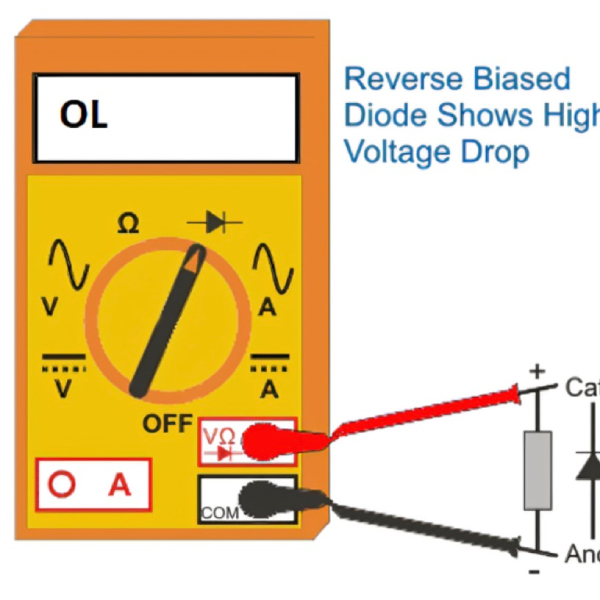

A: Look for visible damage or measure across the diode with a multimeter. No current flow in either direction indicates failure.

Q: Are all flywheel diodes the same?

A: No. They vary by type, such as standard, fast recovery, and Schottky, each suited for different applications.

Flywheel diodes are crucial for managing voltage spikes in circuits with inductive loads. Proper selection, installation, and maintenance of these components are essential for the robust operation of electronic systems.