Introduction to SIC Diodes

Silicon Carbide (SiC) diodes are at the core of modern power electronics. They outshine traditional diodes in various ways. With superior efficiency, SiC diode handle high voltages and temperatures with ease. Their robustness allows for smaller, lighter, and more reliable systems. These diodes are key in industries where power and thermal management are critical. This includes electric vehicles, renewable energy, and industrial power supplies. The improved performance of SiC diodes stems from Silicon Carbide’s unique properties. This semiconductor material has a high thermal conductivity. This means it can dissipate heat effectively. It also has a wide bandgap. This enables the diode to operate at high voltages without breaking down. The switch from silicon to SiC in diodes marks a significant tech advancement. It’s a shift that promises to reshape power electronics, making them more efficient. As we delve deeper, we’ll explore the key benefits and applications of SiC diodes. We’ll also discuss the latest breakthroughs in fabrication.

Key Benefits of SIC Diodes Over Traditional Diodes

SiC diodes offer several advantages that make them superior to conventional silicon diodes. First and foremost, the high thermal conductivity of silicon carbide allows SiC diodes to operate efficiently at higher temperatures. This characteristic enables designs with less cooling requirement, thereby simplifying systems and reducing overall costs.

Additionally, SiC diodes possess a significantly wider bandgap compared to traditional diodes. This property permits them to endure higher voltages without suffering from breakdown. The result is an increased reliability and lifespan of the devices, especially in applications where they are subjected to harsh electrical stresses.

Furthermore, SiC diodes feature fast switching capabilities. They swiftly transition between on and off states, which reduces switching losses. This boost in performance leads to more energy-efficient systems and contributes to lower energy consumption in application areas.

Another pivotal advantage is the reduced size of SiC diodes. Due to their high power density, these diodes can function effectively in a smaller form factor. Consequently, devices utilizing SiC diodes can be more compact, which is desirable in space-constrained applications.

Lastly, the superior efficiency of SiC diodes translates into less heat generation during operation. This reduces the need for extensive thermal management systems, further decreasing the size and complexity of power electronic devices.

By integrating these benefits, SiC diodes are setting new standards in the power electronics world. They are enabling the development of smaller, more efficient, and robust devices capable of operating in extreme conditions without compromise.

Recent Breakthroughs in SIC Diode Fabrication

The sic diode fabrication process has seen impressive progress recently. Key developments focus on improving material quality and production efficiency. We will highlight some of the groundbreaking enhancements.

Enhanced Purity of Silicon Carbide Material

Manufacturers now achieve higher purity in Silicon Carbide. This step reduces defects leading to better performance.

Advanced Growth Techniques for SiC Crystals

Innovative growth methods enable larger, more uniform SiC crystals. These advancements are vital for consistent diode quality.

Precision Doping Control

Precision doping improves the electrical characteristics of SiC diodes. This ensures that diodes can withstand high voltages and temperatures.

Improved Wafer Production

New processes deliver smoother, defect-free wafers. These improve the overall yield, reducing costs in the long term.

Scalable Manufacturing Methods

Scalable production techniques are in place to meet growing demand. This ensures a steady supply of high-quality SiC diodes for various applications.

These breakthroughs are setting a new standard in sic diode production. They prepare the industry for next-generation power electronics. Furthermore, they promise enhanced performance and reliability for users worldwide.

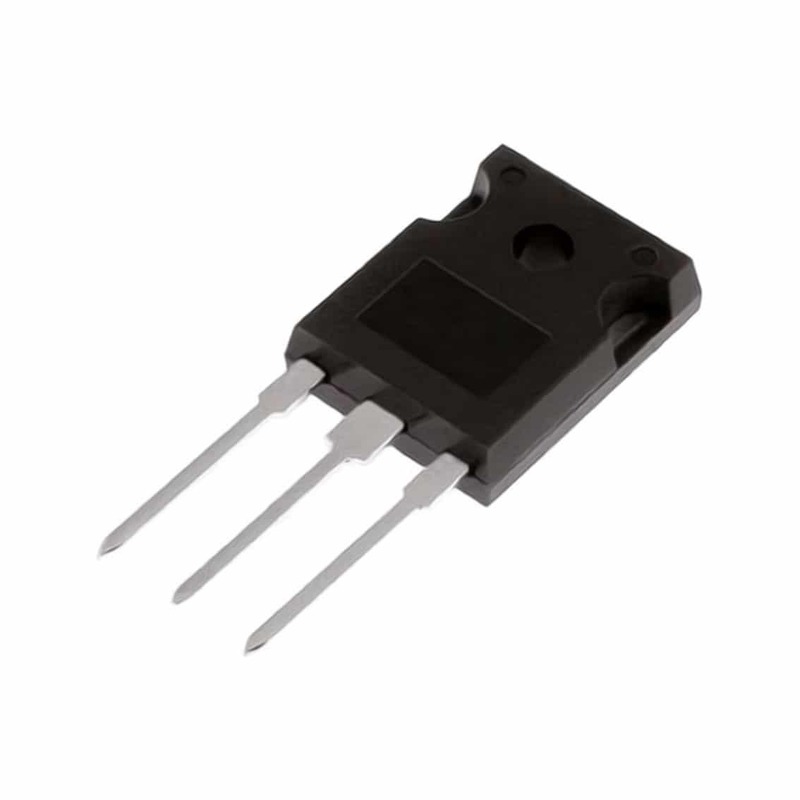

SIC Diodes in Power Electronics Applications

The integration of SiC diodes into power electronics has revolutionized the industry. Their unique characteristics have opened doors to numerous applications, where performance, efficiency, and reliability are paramount. These are a few areas where SiC diodes are making a significant impact:

- Electric Vehicles (EVs): SiC diodes contribute to the efficiency of EV powertrains. They enable faster charging and better mileage, thanks to their high thermal conductivity and swift switching.

- Renewable Energy Systems: In solar inverters and wind turbine converters, SiC diodes help in achieving better power conversion. This leads to more energy being fed into the grid from renewable sources.

- Power Supplies: Whether it’s for industrial, medical, or telecommunications equipment, SiC diodes enhance the power supply reliability. Their ability to handle high voltages and temperatures is critical here.

- Consumer Electronics: The compact size of SiC diodes allows for slimmer designs in devices like laptops and smartphones without compromising on power capabilities.

- Rail Transport: SiC diodes improve the efficiency and dependability of rail systems’ power converters. They help in handling the dynamic power demands of modern trains.

Through these applications, SiC diodes play a crucial role in advancing power electronics. Their durability and efficiency not only elevate device performance but also push the boundaries of what’s possible in power management solutions.

Challenges and Solutions in SIC Diode Manufacturing

In the manufacturing of SiC diodes, several challenges surface, each requiring innovative solutions to maintain the pace of advancement in power electronics.

Material Quality and Supply Issues

One major hurdle is ensuring the consistent quality of silicon carbide material. Impurities and crystal defects can severely affect diode performance. Tackling this, manufacturers have refined purification processes, enhancing the quality of SiC material. Additionally, the establishment of secure and reliable supply chains for high-grade silicon carbide is crucial to meet the growing industry demand.

Production Yield Optimization

Production yield is another significant challenge where any inefficiencies can lead to higher costs and wasted materials. Advanced inspection techniques and quality control systems have been implemented. These steps are critical in identifying defects early and improving the overall yield of SiC diode production lines.

Cost Reduction Strategies

High production costs of SiC diodes, mainly due to intricate processing requirements, are a barrier. To counteract this, manufacturers are continually developing more cost-effective production methods. Bulk growth of SiC crystals and more efficient doping techniques have been introduced to reduce production expenses without sacrificing diode quality.

Equipment and Process Control

The complexity of equipment and processes needed to manufacture SiC diodes also presents a challenge. Maintaining precise control over the manufacturing environment is essential for achieving the desired diode characteristics. Upgrading to automation and employing sophisticated process control technologies allows for better consistency and process efficiency.

Despite these challenges, the industry continues to innovate and find solutions that push the capabilities of SiC diodes further. This continuous improvement supports their growing role in contemporary power electronics applications, promising enhanced performance and reliability.

Impact of SIC Diodes on Energy Efficiency

The impact of SiC diodes on energy efficiency is profound. These diodes have become a critical component in power electronics due to their superior ability to convert energy with minimal loss. Here we discuss the various ways SiC diodes contribute to energy efficiency.

- Reduced Energy Loss: SiC diodes have lower switching losses compared to traditional diodes. This means less energy is wasted during power conversion processes.

- Enhanced Thermal Management: Given their high thermal conductivity, SiC diodes dissipate heat more effectively. This reduces the need for energy-intensive cooling systems.

- Greater Efficiency Under High Temperatures: SiC diodes maintain their performance at elevated temperatures where traditional diodes would fail. This ensures consistent energy efficiency even under harsh conditions.

- Compact Power Systems: The high power density of SiC diodes allows for smaller components. Compact systems tend to require less energy to operate.

- Longer Lifespan: The robustness of SiC diodes leads to a longer operational life, meaning fewer replacements and a reduction in material and energy consumption over time.

By improving the way power is managed and converted, SiC diodes have a direct impact on reducing the energy footprint of various applications. Their contribution is especially notable in fields that demand high power efficiency, like electric vehicles and renewable energy systems. With ongoing advancements in SiC diode technology, we can expect even further improvements in energy efficiency across multiple industries.

Future Trends in SIC Diode Technology Development

As sic diode technology continues to evolve, future trends suggest exciting developments ahead. Innovations will likely focus on the following areas:

- Material Advancements: Researchers are working on creating even purer silicon carbide materials. They strive for fewer defects to boost diode performance.

- Enhanced Device Architecture: The architecture of SiC diodes is bound to improve. This will allow for more efficient power flow and heightened performance.

- Integration with Other Semiconductors: Combining SiC with other semiconductor materials could lead to hybrid devices. These may offer unique advantages in power electronics.

- Smarter Production Techniques: The industry aims to develop smarter, more automated production processes. These will increase yield and reduce costs.

- Miniaturization: As with all electronics, the push towards smaller, more efficient components will continue. This could lead to even more compact SiC diodes.

- Wider Application Range: SiC diodes will find new applications as their benefits become more widely recognized.

These trends point to a future where SiC diodes play an even more central role in power electronics. Advancements in material science and fabrication techniques are central in driving these trends. They pave the way for new possibilities, enhancing the capability and impact of SiC diodes on technology and sustainability.

The Role of SIC Diodes in Sustainable Technology

SiC diodes are a cornerstone for sustainable technology development. Their ability to handle high power while being energy efficient makes them an asset in eco-friendly applications. For instance, in electric vehicles (EVs), SiC diodes make powertrains more efficient. This leads to longer battery life and reduced charging times. Also, SiC diodes are critical in renewable energy. Their efficiency improves solar inverter and wind turbine performance. This results in more clean energy entering our grid.

Another key point is the reduction of electronic waste. The longevity of SiC diodes means fewer replacements over time. This contributes to less waste and a lower environmental impact. Moreover, their high thermal conductivity makes extensive cooling systems unnecessary. As a result, we see a decrease in energy use for cooling electronics.

Lastly, advancements in SiC diode technology allow for greener production methods. These methods are aimed at reducing harmful emissions and conserving resources during manufacturing. As technology progresses, we can expect SiC diodes to play an even larger part in fostering an eco-conscious and efficient future.