How to cut clear acrylic with diode laser

Cutting clear acrylic with a diode laser can be challenging but achievable with the right techniques and settings. This guide will walk you through the process step-by-step to ensure successful and precise cuts. We’ll cover everything from the tools you’ll need to the best practices for achieving clean, accurate results.

Understanding Clear Acrylic and Diode Lasers

Understanding Clear Acrylic and Diode Lasers

What is Clear Acrylic?

Clear acrylic, also known as polymethyl methacrylate (PMMA), is a transparent plastic material often used as an alternative to glass. It is lightweight, durable, and versatile. Its high transparency makes it ideal for displays, signs, and protective barriers.

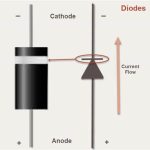

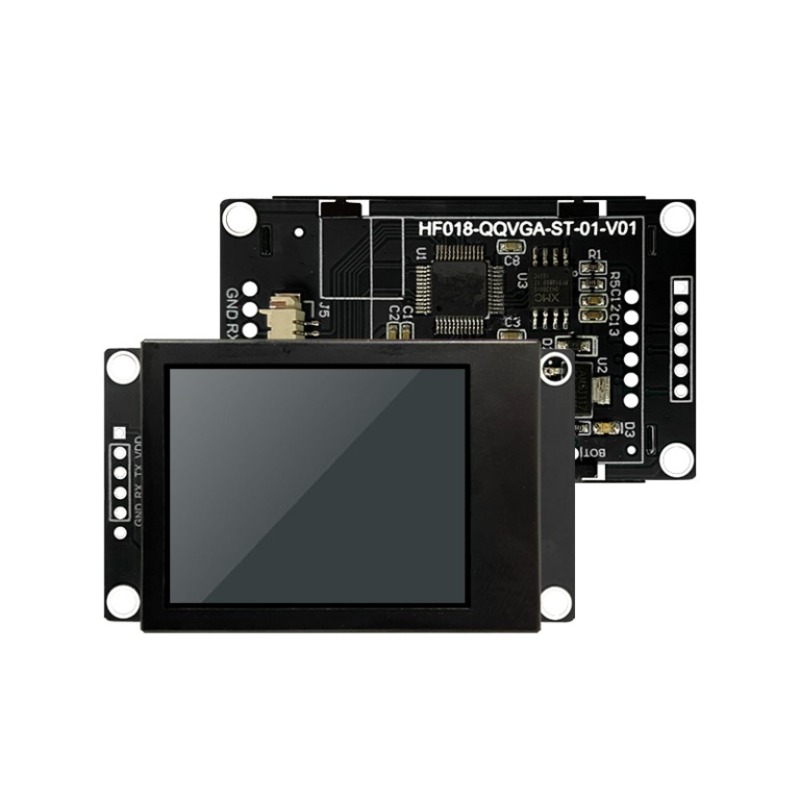

What is a Diode Laser?

A diode laser is a solid-state device that emits a coherent beam of light. These lasers are commonly used in various applications, including cutting, engraving, and marking materials. Diode lasers are compact, efficient, and affordable, making them popular among hobbyists and professionals.

Why Cut Clear Acrylic with a Diode Laser?

Cutting clear acrylic with a diode laser offers several advantages. It provides precise, clean cuts with minimal material waste. The process is also faster and more consistent compared to traditional cutting methods. However, clear acrylic poses unique challenges due to its transparency, which can interfere with the laser’s effectiveness.

Preparing for the Cutting Process

Safety First

Before starting, ensure you have the necessary safety equipment. Wear safety goggles designed for laser protection. Additionally, ensure your workspace is well-ventilated, as cutting acrylic can produce harmful fumes.

Selecting the Right Diode Laser

Choose a diode laser with sufficient power for cutting clear acrylic. Typically, a 5-10 watt laser is recommended for cutting thin acrylic sheets (up to 5mm). For thicker sheets, a more powerful laser may be necessary.

Preparing the Acrylic Sheet

Start by cleaning the acrylic sheet to remove dust and debris. Use a soft cloth and mild detergent. Ensure the sheet is dry before proceeding. Place the acrylic sheet on a flat, stable surface to prevent movement during cutting.

Setting Up the Diode Laser

Setting Up the Diode Laser

Mounting the Laser

Secure the diode laser to a stable platform or machine. Ensure the laser is properly aligned and focused on the acrylic sheet. Adjust the height and angle for optimal cutting performance.

Adjusting Laser Settings

Different types of acrylic and thicknesses require specific laser settings. Begin with the following general guidelines:

- Laser Power: Start with a lower power setting (20-30%) and gradually increase if needed.

- Cutting Speed: Use a moderate speed to balance between speed and precision. A slower speed often results in cleaner cuts.

- Frequency/Pulse Rate: Adjust the frequency to suit your material. Higher frequencies may produce smoother cuts but can generate more heat.

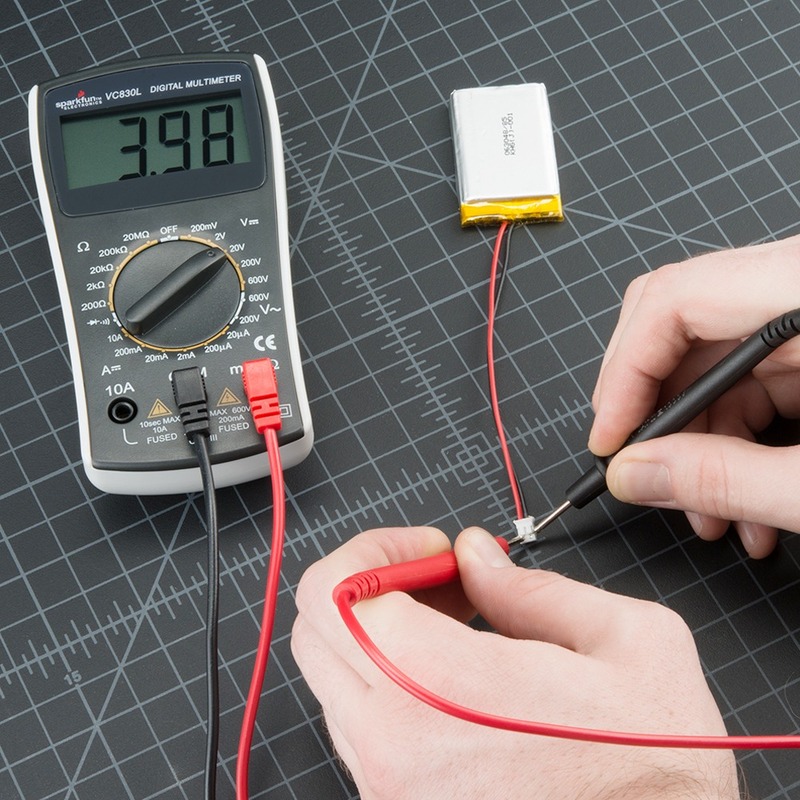

Testing and Calibration

Perform a test cut on a scrap piece of acrylic. Check the cut for precision, edge quality, and any signs of melting. Adjust the laser settings as needed. Repeat the test until satisfied with the results.

Cutting the Clear Acrylic

Creating a Cutting Plan

Design a cutting plan using CAD software or similar tools. This plan should include the desired shapes, dimensions, and cutting paths. Export the design to a compatible format for your laser cutting machine.

Positioning the Acrylic Sheet

Place the acrylic sheet on the cutting bed of the laser machine. Secure it with clamps or adhesive backing to prevent movement. Ensure it is properly aligned according to your cutting plan.

Starting the Cut

Begin the cutting process. Monitor the laser and acrylic sheet closely. Ensure the cutting path follows the desired design. Be prepared to stop the machine if you notice any issues, such as excessive melting or misalignment.

Managing Heat and Debris

Clear acrylic can melt or produce debris during cutting. Use a cooling system, such as air assist or a fan, to minimize heat buildup. Remove any debris to prevent interference with the cutting process.

Post-Cutting Practices

Post-Cutting Practices

Inspecting the Cut

Once the cut is complete, inspect the acrylic sheet. Check the edges for smoothness and precision. Look for any signs of burning, charring, or melting. Make adjustments to the laser settings if necessary for future cuts.

Cleaning the Edges

Remove any rough edges or burrs with fine-grit sandpaper or a deburring tool. Clean the acrylic sheet again to remove any residue from the cutting process.

Finishing Touches

For a polished finish, you can flame-polish the edges using a propane torch. Move the flame steadily along the edge to smooth and clarify it. Be cautious to avoid overheating and damaging the acrylic.

Troubleshooting Common Issues

Troubleshooting Common Issues

Incomplete Cuts

If the laser doesn’t cut through the acrylic completely, increase the power setting or slow the cutting speed. Ensure the laser beam is properly focused and aligned.

Melting and Burning

Excessive melting or burning indicates too much power or a slow cutting speed. Reduce the power setting or increase the speed. Ensure adequate cooling and ventilation during cutting.

Poor Edge Quality

Rough or jagged edges can result from improper laser settings or material movement. Adjust the speed, power, and focus settings. Secure the material firmly to prevent shifting during cutting.

Advanced Tips and Techniques

Using Masking Tape

Applying masking tape to the surface of the acrylic sheet can help reduce reflections and prevent the laser beam from scattering. This can improve cutting precision and edge quality.

Multiple Passes

For thicker acrylic sheets, consider using multiple passes at lower power settings. This can reduce heat buildup and produce cleaner cuts.

Specialized Lenses

Some diode lasers offer specialized lenses for cutting acrylic. These lenses can enhance focus and precision, improving the overall quality of the cut.

Some key trends

How to cut clear acrylic with diode laser

The trends in the diode market are constantly evolving due to advancements in technology and shifting demands across various industries. Here are some key trends currently seen in the diode market:

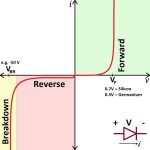

Advancements in Semiconductor Materials:

Traditional silicon diodes are increasingly complemented by diodes made from newer materials such as Silicon Carbide (SiC) and Gallium Nitride (GaN). These materials offer superior performance in terms of efficiency, thermal management, and voltage capacity, making them ideal for high-power and high-frequency applications.

Growth in Automotive Electronics:

With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), the demand for high-efficiency diodes has surged. Diodes are essential in power conversion, battery management, and various other electronic systems in modern vehicles.

Increased Demand for Power Efficiency:

As energy efficiency becomes a larger priority across industries, diodes that contribute to lower power consumption and heat generation are in high demand. This is especially true in power supplies, renewable energy systems, and data centers.

Miniaturization and Integration:

There is a continuous trend towards the miniaturization of electronic components, including diodes. Smaller and more integrated diodes are required for compact devices such as smartphones, wearables, and other consumer electronics.

Expansion of 5G and Telecommunication Infrastructure:

The rollout of 5G networks requires increasingly sophisticated and efficient diodes to handle higher data rates and more stringent performance requirements. This drives innovations in high-speed diodes capable of operating at higher frequencies.

Growth in Renewable Energy:

The expansion of solar power and other renewable energy sources has led to a higher demand for efficient rectifier diodes that can handle the conversion of AC to DC power with minimal loss.

Industrial Automation and IoT:

The growth of the Internet of Things (IoT) and industrial automation requires reliable diodes for sensors, connectors, and various control systems to ensure seamless and dependable operations.

In summary, the diode market is experiencing notable growth and innovation driven by advancements in materials, the rise of electric vehicles, demand for energy efficiency, progress in telecommunications, expansion of renewable energy, and the proliferation of IoT and industrial automation.

Conclusion

Conclusion

How to cut clear acrylic with diode laser

Cutting clear acrylic with a diode laser requires careful preparation, precise settings, and attention to detail. By following this comprehensive guide, you can achieve clean, accurate cuts for your projects. Remember to prioritize safety, thoroughly test and calibrate your laser, and address any issues promptly. With practice and experimentation, you’ll master the art of cutting clear acrylic with a diode laser.